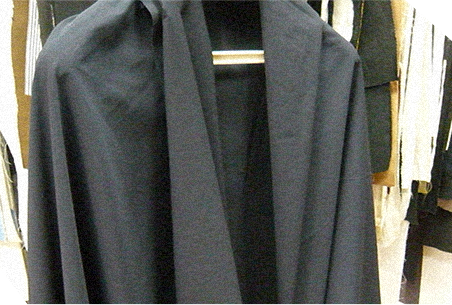

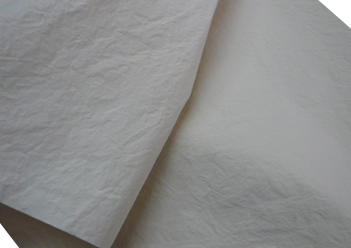

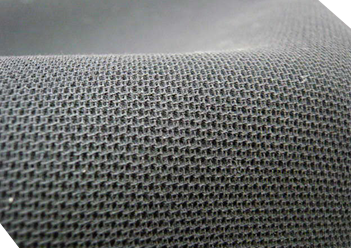

Gabardine woven with ultra-hard twist yarn

By using ultra-hard twist yarn with 2,000 twists/meter, which is double the value for regular ply yarn twist for the ZZ reverse lay, a supple yet firm fabric that is wrinkle-resistant yet drapes and moves well when made into a product is achieved.

This material is representative of Kaneta woven fabrics that are made as lustrous as possible by subjecting the yarn to processes such as gas singeing, cold batch dyeing, and mercerizing.